Update: Still waiting on replacement firmware from TronXY.

TLDR; I messed with the firmware and lost the Z-adjust button on the machine. But I figured out how to manually adjust Z.

Blame me for my upgrading.

The TronXY X5SA uses a F-Mini control board from www.cbd-3d.com. On the cbd-3d website they offer a data download link. That link gets you a windows program that provides details on the various items they make, including firmware updates. Unfortunately, it does not tell you what firmware version is being offered.

I put the firmware update on my micro-SD card and turned the printer on. It made a few beeps which seemed to indicate a firmware upgrade in progress. It rebooted and I made a successful print.

Unfortunately, every print after that has failed because I cannot change the z-offset anymore.

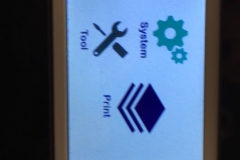

Before the upgrade, v1.4.0RC13m4:

After the upgrade, v1.4.1RC2m4:

On the plus side, this new version has a working wifi menu.

On the bad side, pressing the “Z-Offset” button gets me this screen…

With no way to access the z-offset, it’s pretty hard to fine tune the base layer.

*sad MrRobertsScience*

I’ve contacted cbd-3d.com for assistance. I’m hesitant to contact TronXY – they haven’t responded to any of my recent emails.

Update 2/25/2018: I spent some time hooked up to the printer through TTL/USB converter and repetier-host. I tried a lot of different g-code commands. Based on the commands that worked and those that didn’t, I’m fairly certain this is not a rip-off of marlin, smoothie ware, or reprapfirmware (what Duet uses).

I left the printer running … the first half of the print looks amazing- we’ll see if it finishes properly.

Update #2 2/25/2018: Heard back from cbd-3d.com – “The firmware of TronXY is customized, not a generic firmware. If you need to update, you can contact TronXY company and they will handle it.”

Update #3 3/17/2018: Here’s my G-code for changing the Z-offset.

M8084 Z1.5 ; Set Z-Offset to 1.5mm

M8500 ; Save settings.

G0 Z10; Lower Z axis to prevent crashing during homing.

G28 ; Home Axis

G0 Z0 ; Check for paper tightness